The customer is now able to inject a large quantity of boron (350 kg/min) into the slag pot within a very short time.

The new STEIN system is replacing an existing system of a competitor - The new installation will minimize system failures in the future and save costs.

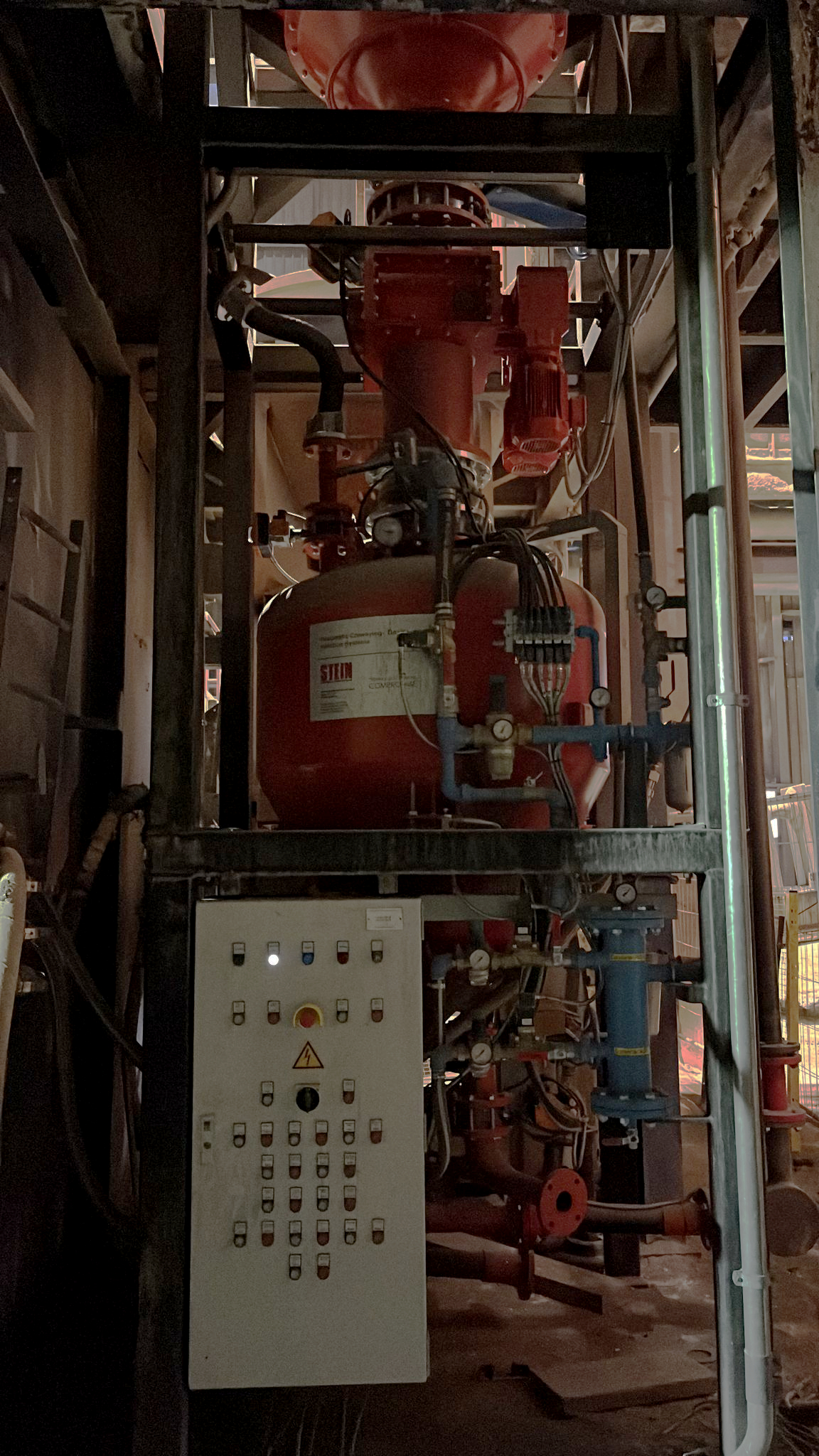

Systems characteristics:

- Hopper with 6 m³ and dispenser with 1 m³ capacity, small footprint of just 1,8 m x 1,6 m

- Lump breaker for crushing down agglomerated boron lumps into injectable grain sizes

- Two outlets at the dispenser allowing individual injection at both converters

- Direct reaction of Boron in the slag through precise injection amount into the stream

- Simple installation, individual configuration to customers’ needs

- “Stand-alone unit” with own PLC for realization of automated injection process

Need more information? Contact us!